Xiangtan Lufeng Machinery Co., Ltd

Main Products:rotary furance ,ingot casting machine , electrolysis machine system

Building B6, Accelerator Park, No. 18 Gaoxin Road, Xiangtan, Hunan Province, China

+86-17773276726

PRODUCT NAME: ingot casting machine

Recycled aluminum is a kind of aluminum alloy or aluminum metal obtained by remelting and refining waste aluminum and aluminum alloy materials or aluminum containing wastes, which is an important source of metal aluminum. Recycled aluminum is mainly in the form of aluminum alloy.

There are 3003, 3105, 3004, 3005, 5050 and so on, among which 3105 alloy is mainly produced. In order to ensure that the chemical composition of the alloy material meets the technical requirements and the technological requirements of pressure processing, some primary aluminum ingots should be added when necessary.

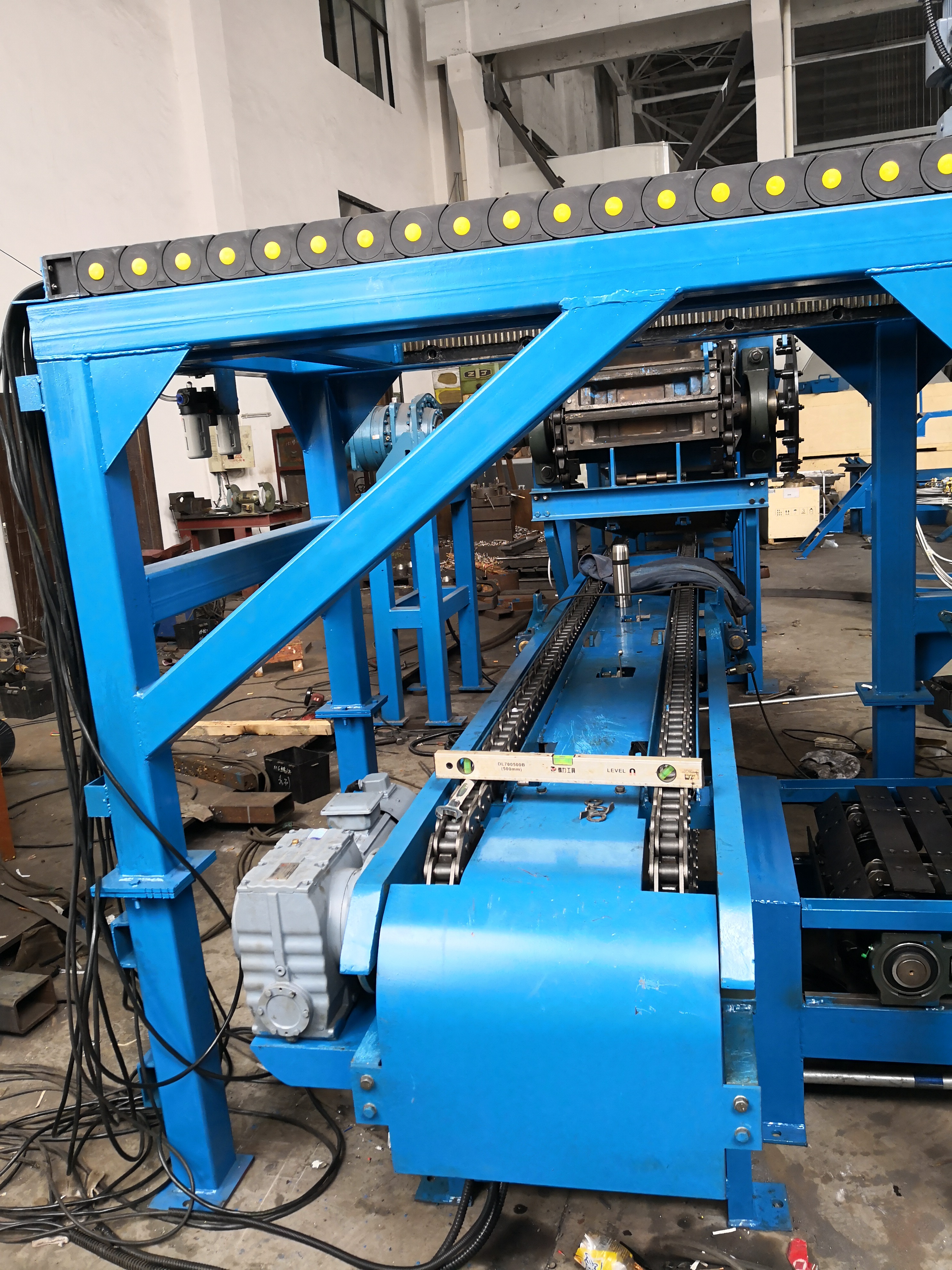

Copper Aluminum ZInc Lead Ingot Continous Casting Machine

Recycled cast aluminum alloy. Only a small part of waste aluminum is recycled into deformed aluminum alloy, About 1 / 4 deoxidizers (deoxidized aluminum ingots) are produced for steelmaking, most of which are used for recycling aluminum alloy for casting. A380 and adcl0, which are widely used in the United States, Japan and other countries, are basically regenerated from scrap aluminum.

Recycled aluminum can be cast into aluminum ingot, aluminum bar, die-casting aluminum, etc. Continuous ingot casting machine can cast aluminum ingot, copper ingot, lead ingot, magnesium ingot, zinc ingot, tin ingot, steel ingot, iron ingot, etc.

Continous ingot cast machine has 5 mainly parts: diverter, stepless speed regulating motor, demoulding hammer, electrical control cabinet, cooling spray device.

What is difference between copper ingot machine and aluminium ingot making machine?

As we know the melting temperature of aluminum scrap is much lower than copper's, so as same as the casting temperature, copper need higher temperature by die casting. Therefore we use different material for manufacture die casting molds. Mold for making copper ingot has good ability in heating-proof. Continuous casting ingot machine has stepless speed regulating motor, then we can adjust ingot manufacturing speed easily.

PRODUCT PICTURES:

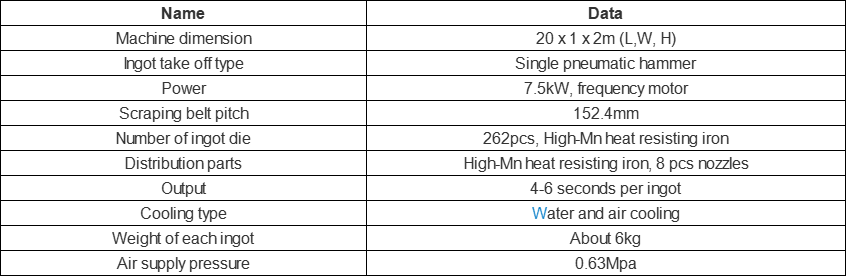

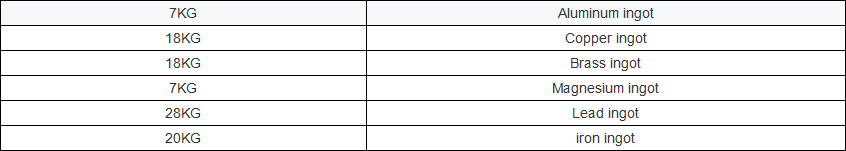

SPECIFICATIONS: Copper Aluminum ZInc Lead Ingot Continous Casting Machine

Xiangtan Lufeng Machinery Co., Ltd. was established in 2010 and is located in the Industrial Park of Hunan Xiangtan High-tech Zone. Through more than 10 years of precipitation and development, Lufeng company has made many achievements in the design and manufacture of high-quality copper&lead&zinc smelting equipment.

Today, Lufeng has become one of the best manufacturers of high-quality smelting equipment in China and abroad, such as copper&lead smelting furnace, linear ingot casting machine, disc ingot casting machine, lead pot refining system, lead-acid battery crushing and sorting system, copper&lead&zinc electrolysis system, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba