Xiangtan Lufeng Machinery Co., Ltd

Main Products:rotary furance ,ingot casting machine , electrolysis machine system

Building B6, Accelerator Park, No. 18 Gaoxin Road, Xiangtan, Hunan Province, China

+86-17773276726

PRODUCT NAME:

lufeng factory customized size of lead refining furnace stove Q245 materials best thickness

Reflection refining furnace

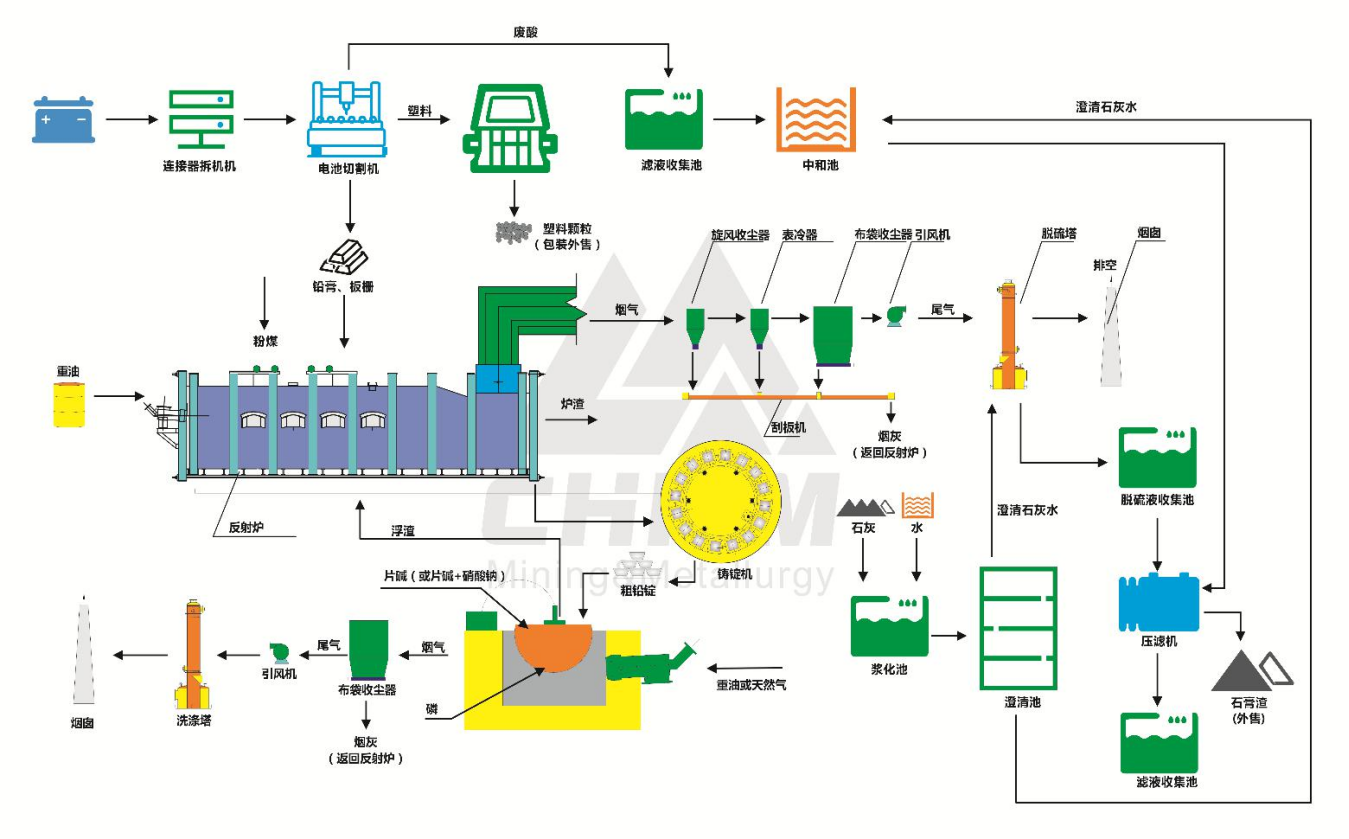

The present invention discloses a bottom blowing process for alkaline refining of regenerated lead by fire method. After the crude lead liquid is poured into the refining furnace from the melting furnace, argon gas is introduced from the bottom. When the temperature of the lead liquid drops to about 330 ℃, slag is skimmed, and the lead copper content is reduced to about 0.1% by melting and removing copper. After skimming, sulfur powder is sprayed into the bottom of the refining furnace to further remove copper. The temperature is raised to 450-480 ℃, and the reaction is carried out for 30-60 minutes. The sulfide slag is removed to complete the copper removal process; When the lead liquid temperature is about 450 ℃, powdered Sodium nitrate and sodium hydroxide are blown from the bottom of the refining furnace. After reaction for 30min, NaCl powder is blown from the bottom of the refining furnace with argon gas to complete the arsenic, antimony and tin removal process. The loss of said bottom blowing process method, refining agent and/or alloy is greatly reduced; There is only inert gas with low solid solubility in the lead liquid, which is not easily oxidized by the lead liquid and lead ingot. There is no lead slag inside the lead liquid and lead ingot. When using recycled lead, there is less lead slag and the slag yield is low; During the refining process, the surface of the lead liquid is always protected by argon gas, which can be used for high-temperature Ag removal operations. The regenerated lead contains low Ag content; The argon gas blown into the bottom will float together with small bismuth compound particles, resulting in low bismuth content in lead ingots

PRODUCT PICTURES:

lufeng factory customized size of lead refining furnace stove Q245 materials best thickness

lufeng factory customized size of lead refining furnace stove Q245 materials best thickness

lufeng factory customized size of lead refining furnace stove Q245 materials best thickness

SPECIFICATIONS:

lufeng factory customized size of lead refining furnace stove Q245 materials best thickness

Xiangtan Lufeng Machinery Co., Ltd. was established in 2010 and is located in the Industrial Park of Hunan Xiangtan High-tech Zone. Through more than 10 years of precipitation and development, Lufeng company has made many achievements in the design and manufacture of high-quality copper&lead&zinc smelting equipment.

Today, Lufeng has become one of the best manufacturers of high-quality smelting equipment in China and abroad, such as copper&lead smelting furnace, linear ingot casting machine, disc ingot casting machine, lead pot refining system, lead-acid battery crushing and sorting system, copper&lead&zinc electrolysis system, etc.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba