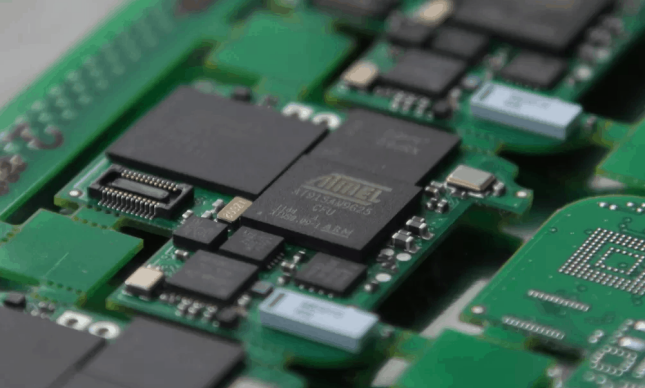

Today, we will introduce four testing methods for PCBA after SMT placement: First Item Inspection, LCR Measurement, AOI Inspection, and Flying Probe Testing.

1. The First Item Inspection system is an integrated system that allows direct input of the production BOM into the system. The built-in testing units will automatically test the first article prototype and compare it with the input BOM data to confirm whether the produced first article prototype meets quality requirements. This system is convenient, with an automated testing process that can reduce errors due to human factors. It can save labor costs, but it requires a significant initial investment. It is widely used in the current PCB SMT industry.

2. LCR Measurement is suitable for some simple circuit boards with fewer components, no integrated circuits, and only components mounted on the board. After the placement is completed, there is no need for reflow. Directly use the LCR to measure the components on the circuit board and compare them with the rated values of the components on the BOM. If there are no abnormalities, formal production can begin. This method is widely adopted due to its low cost (as long as there is an LCR instrument, the operation can be performed).

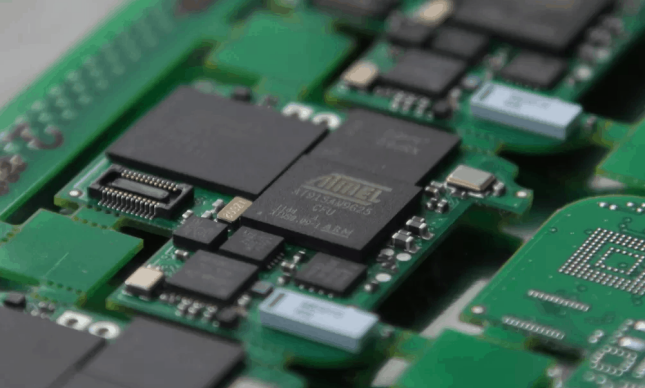

3. AOI Inspection is very common in the SMT industry and is suitable for all circuit board production. It mainly determines the soldering issues of components through their physical characteristics and can also determine whether there are any wrong component issues on the circuit board by checking the color of the components and the silk screen on the ICs. Basically, every SMT production line will be equipped with one to two AOI devices as standard.

4. Flying Probe Testing is usually used in small batch production. Its characteristic is convenient testing, strong program variability, and good universality, which can basically test all types of circuit boards. However, the testing efficiency is relatively low, and the testing time for each board will be long. This test needs to be conducted after the product has passed through the reflow oven. It mainly determines whether there are short circuits, open soldering, or wrong component issues in the circuit board by measuring the resistance between two fixed points.

Next we will learn other three testing ways about PCBA.

English

English Español

Español Português

Português русский

русский français

français 日本語

日本語 Deutsch

Deutsch Tiếng Việt

Tiếng Việt Italiano

Italiano Nederlands

Nederlands ไทย

ไทย Polski

Polski 한국어

한국어 Svenska

Svenska magyar

magyar Malay

Malay বাংলা

বাংলা Dansk

Dansk Suomi

Suomi हिन्दी

हिन्दी Pilipino

Pilipino Türk

Türk Gaeilge

Gaeilge عربى

عربى Indonesia

Indonesia norsk

norsk اردو

اردو čeština

čeština Ελληνικά

Ελληνικά Українська

Українська Javanese

Javanese فارسی

فارسی தமிழ்

தமிழ் తెలుగు

తెలుగు नेपाली

नेपाली Burmese

Burmese български

български ລາວ

ລາວ Latine

Latine Қазақ

Қазақ Euskal

Euskal Azərbaycan

Azərbaycan slovenský

slovenský Македонски

Македонски Lietuvos

Lietuvos Eesti Keel

Eesti Keel Română

Română Slovenski

Slovenski मराठी

मराठी Српски

Српски 简体中文

简体中文 Esperanto

Esperanto Afrikaans

Afrikaans Català

Català עִברִית

עִברִית Cymraeg

Cymraeg Galego

Galego 繁体中文

繁体中文 Latvietis

Latvietis icelandic

icelandic יידיש

יידיש Беларус

Беларус Hrvatski

Hrvatski Kreyòl ayisyen

Kreyòl ayisyen Shqiptar

Shqiptar Malti

Malti lugha ya Kiswahili

lugha ya Kiswahili አማርኛ

አማርኛ Bosanski

Bosanski Frysk

Frysk ជនជាតិខ្មែរ

ជនជាតិខ្មែរ ქართული

ქართული ગુજરાતી

ગુજરાતી Hausa

Hausa Кыргыз тили

Кыргыз тили ಕನ್ನಡ

ಕನ್ನಡ Corsa

Corsa Kurdî

Kurdî മലയാളം

മലയാളം Maori

Maori Монгол хэл

Монгол хэл Hmong

Hmong IsiXhosa

IsiXhosa Zulu

Zulu Punjabi

Punjabi پښتو

پښتو Chichewa

Chichewa Samoa

Samoa Sesotho

Sesotho සිංහල

සිංහල Gàidhlig

Gàidhlig Cebuano

Cebuano Somali

Somali Точик

Точик O'zbek

O'zbek Hawaiian

Hawaiian سنڌي

سنڌي Shinra

Shinra հայերեն

հայերեն Igbo

Igbo Sundanese

Sundanese Lëtzebuergesch

Lëtzebuergesch Malagasy

Malagasy Yoruba

Yoruba